Einleitung

Warum ESD-Schutz?

Die elektrostatische Entladung (electrostatic discharge) begegnet uns tagtäglich im Alltag:

Der „Schlag“, den man an der Autotür bekommt, abstehende Haare, wenn man sich seiner Mütze entledigt

oder wenn es zwischen zwei Menschen „funkt“.

Was für uns ein kurzer Schreck und meist nur lästig ist, ist für elektronische Komponenten, die mit kleinen und

kleinsten Halbleiterbauelementen bestückt sind, schnell ein Totalschaden.

Gerade bei trockener Luft sind Entladungen mit einem Potential von 10 000 Volt keine Seltenheit.

Für die FAST LTA AG ist deshalb die Vermeidung von ESD eines der höchsten Gebote.

Viele durch ESD entstandene Schäden werden im ungünstigsten Fall erst nach einiger Zeit durch den

Kunden festgestellt und führen dann zu hohen Reparatur- oder Austauschkosten. Viel schlimmer als der

finanzielle ist zusätzlich der darauf folgende Image-Schaden, wenn durch einen verschleppten Fehler ein Produkt oder eine

ganze Produktcharge beeinträchtigt wurde.

Wenn bei der FAST LTA AG Elektronikkomponenten ohne ESD-Schutz eingehen, ist von einer potentiellen

Vorschädigung auszugehen, die sich erst zukünftig auswirkt. Die Komponente darf somit nicht mehr verwendet werden.

Einführungsvideo

-

-

Geerdetes ESD-Armband tragen.

-

Geerdete ESD-Matte benutzen.

-

ESD-Schuhe tragen

-

Elektronische Komponenten erst aus der ESD-Verpackung entnehmen, wenn zwei der oben genannten Bedingungen erfüllt sind.

-

-

-

ESD-Ablage verwenden

-

ESD-Beutel verwenden

-

-

-

Platinen NIEMALS ohne ESD-Beutel von Hand zu Hand übergeben !!!

-

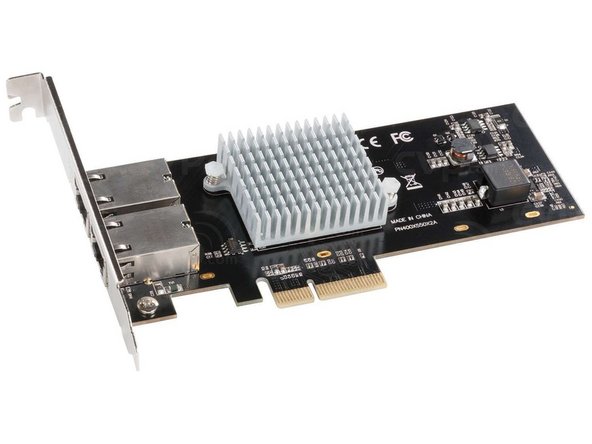

Platinen oder Komponenten NIEMALS an den Goldkontakten berühren !!! Dies hat Ablagerungen vom Handschweiss und damit unter Umständen Korrosion zur Folge. Auf alle Fälle aber eine Beeinträchtigung der Signalqualität gerade bei Highspeed-Verbindungen wie PCIe, SAS zur Folge.

-

-

-

Falls kein ESD-Equipment zur Verfügung steht, kann man die Wahrscheinlichkeit eines Funkenüberschlags vermindern, aber nicht komplett ausschließen, wenn man Folgendes beachtet:

-

Geräte oder Komponenten zuerst am Gehäuse/Metall berühren um einen Potentialausgleich zu schaffen.

-

Bei Übergabe von Komponenten ohne ESD-Verpackung an eine andere Person, die Person erst berühren und die Platine erst dann übergeben.

-

Rückgängig: Ich habe diese Anleitung nicht absolviert.

Ein weiterer Nutzer hat diese Anleitung absolviert.